This article originally appeared in row360 - issue 10

-

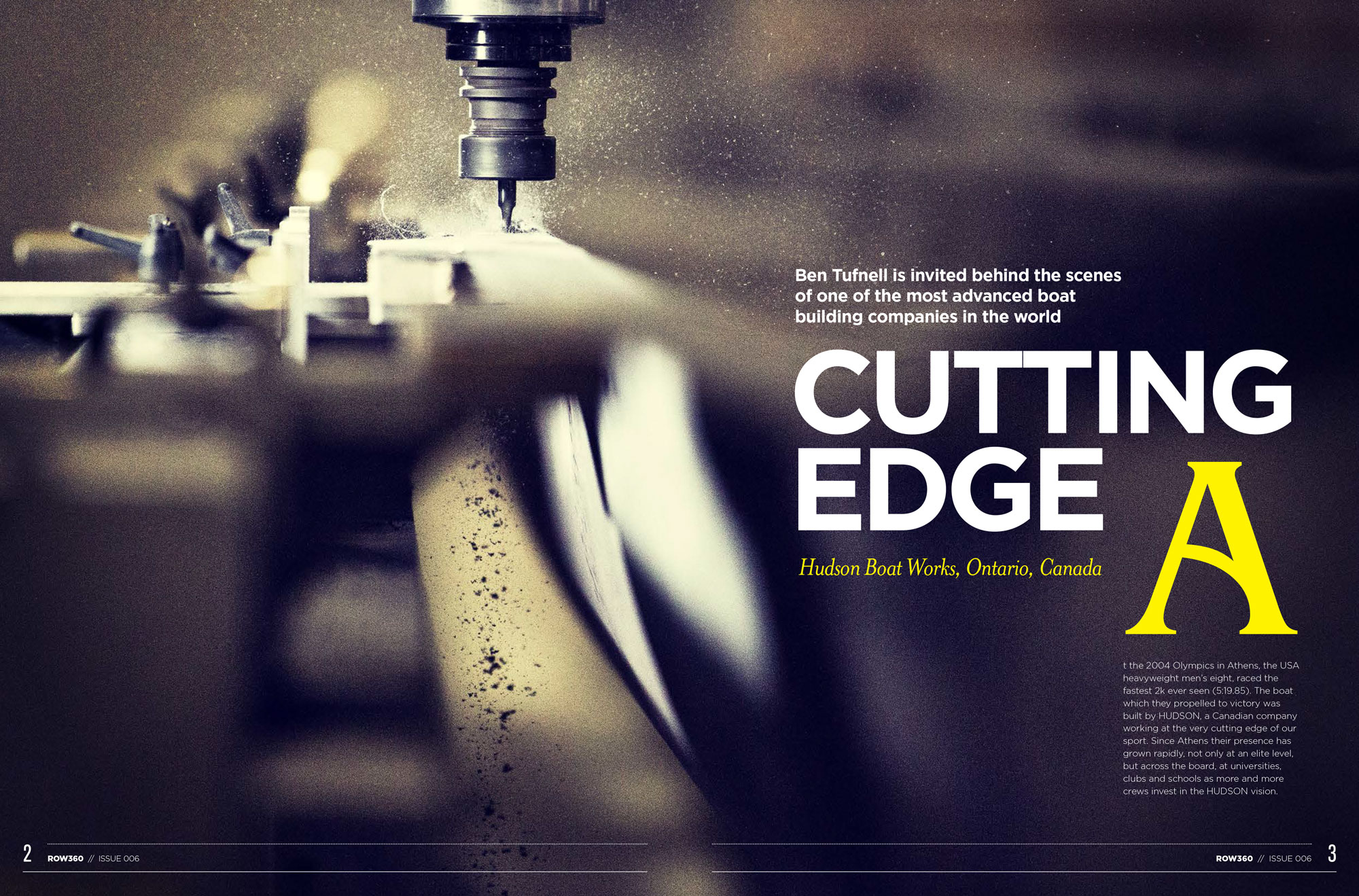

Row360 is invited behind the scenes of one of the most advanced boat building companies in the world

CUTTING EDGE

Hudson Boat Works, Ontario, Canada

MARCH 2016 | At the 2004 Olympics in Athens, the USA heavyweight men’s eight, raced the fastest 2k ever seen (5:19.85). The boat which they propelled to victory was built by HUDSON, a Canadian company working at the very cutting edge of our sport. Since Athens their presence has grown rapidly, not only at an elite level, but across the board, at universities, clubs and schools as more and more crews invest in the HUDSON vision.

In a sport already well-served with long-established brands and where old habits frequently die hard, it’s an impressive feat. Or in their own words, simply “doing the work required to set the pace.”

It’s clear from the moment you walk into HUDSON Boat Works in Ontario, Canada that this is a company whose people are proud of what they do. As Commercial Manager Craig McAllister and Operations Manager Glen Burston escort me onto the factory floor, the Canadian women’s eight is being loaded into a 45 foot shipping container bound for Antwerp, en-route to Rio and the 2016 Olympic Games. Hidden within the hull, I learn, are the signatures of the men and women who built it. Experts in their craft, the factory workers clearly take great satisfaction in their work. “It’s a tradition here that the Olympic boats end up with a series of hidden signatures in them - doesn’t weigh anything, doesn’t hurt anybody and nobody can see it”, Glen tells me, “but it shows these guys care about that boat every bit as much as the customer it is going to.”

The company has gone through several incarnations over the years. HUDSON Boat Works was founded in 1981 by Jack Coughlan and his brother-in-law Hugh Hudson. Previously Jack made wooden oars, but saw sales evaporate almost overnight after composite carbon oars came on the scene in the late ‘70s. Resolving never to be caught out again, Jack changed direction, and in the early ‘90s HUDSON Boat Works became one of the first to produce ‘pre-preg’ carbon composite racing shells.

By ’84 they already had their first medal in an Olympic games and a flurry of medals came in Atlanta in ’96. In fact, to date HUDSON boats have collected over 80 medals from Olympic and Senior World Championship races. The real change of pace however, wasn’t until 2005. “The company wasn’t just making racing shells back then,” explains Glen, “we were building all kinds of other products, some for the rowing industry, some for elsewhere. That was where we felt the fundamental change had to come - if we didn't focus on one product and endeavor to make that one thing better than anyone else, then there was no long term viability - so we shed everything else.” Stripping it all back, they left themselves one clear objective – make the world’s best rowing boats - a decisive and indeed brave move that was to prove wildly successful.

“It took about four years, from around ’05 to ’09, to build the foundations for what we are seeing now” according to Glen. “The first step was to get the right people on board - from the customer’s perspective it wouldn’t have looked like an awful lot was happening in those years. We were building the infrastructure necessary to be who we are today. It was all happening behind the scenes.”

As we continue through the state-of-the-art factory, technology and innovation are everywhere. “We’re using similar materials, construction methods, processes and technologies as the aerospace, Formula 1 or America’s Cup sailing industries” explain’s Craig. “We do it on a budget that is a fraction of what those industries have access to. But our customers expect us to manufacture and develop at a comparable level to those guys and we have to meet that expectation. I think that is where creativity comes in. We don’t have the deep pockets of the aerospace industry, but we do have a wealth of creative and critical thinking combined with a clear vision.”

One way it appears they have been very clever is the investment they have made in their engineering staff. “We spent a long time building our team and we are at a point where we have the talent to construct things like our iPad-controlled laser projection system. We did it in-house for ten percent of what it would have cost to buy-in. It does exactly what we need and is perfectly integrated with our data management engineering systems.”

The ‘iPad’ tablet system is one of many technological advances implemented by HUDSON over the last decade that stands out in an industry historically more ‘spit and dust’ than lasers and touch screens. As we continue I am struck time and again by the level of technology at HUDSON – It’s easy to forget that this is a rowing company. Now almost entirely paperless, the factory manages its production schedule through a cloud-based tablet app. “Staff log in and immediately have access to exactly what’s happening at that moment with each boat in process, so they can make sure everything is happening as it should.” explains Glen. “This approach also facilitates monitoring of critical processes – for example, every cure cycle in the ovens (in which the carbon is cured in the mold) has its own pre-set program.” If at any point the temperature falls more than a few degrees outside the set parameters, it sends a text message and email to the on-call engineer. “So we’re using technology that means we can login at any time, from anywhere in the world and see exactly what’s happening with our manufacturing processes.” From real time data collection on every process to lasers in the ceiling that project where to bond parts, the facility is fully wireless with a digital infrastructure to rival the auto industry.

Continuing on we arrive at the ‘bend test’ machine. Comprising around $150,000 worth of materials, controls and actuators - a machine of this type would typically be beyond the scope of what a regular boat builder would be able to afford. As I’m learning though, this is certainly no ordinary boat builder. “If we were to outsource this technology, it would cost around $500,000 just to have someone come in and build it. It’s a mammoth thing, we built it ourselves and it’s incredibly accurate.” As its name suggests, the bend test machine slightly flexes every hull as it comes off the production line, validating both torsional and longitudinal stiffness. “If something is off in our process, we will see it well before the customer could ever detect it.” Not only does it ensure each individual boat meets the required standard, it means they are continually keeping a very close eye on their manufacturing processes. It allows them to detect and address any quality control issues that may arise early. As they drive down that variation from boat to boat, the effects of any changes to the manufacturing process become increasingly clear.

A Datron high-speed milling machine is another recent addition to HUDSON’s technology arsenal. Their fourth and newest CNC machining centre in the factory, it cuts the amount of time required to create their own rigger and parts molds significantly. Costing $250,000, it is evidence of the constant re-investment in their technology and a desire to ultimately move all parts of the manufacturing process ‘in-house’ to ensure the highest level of quality control.

Constantly testing, researching and advancing their hull shapes, through collaboration with renowned naval architect Britt Chance, the new era of HUDSON shells were the first to market using ‘unsteady flow’ computational fluid dynamics (CFD) analyses. Now working with expert architect Steve Killing, the SHARK hulls are designed for increased stability whilst maintaining their outstanding performance characteristics. In conjunction with the most technologically advanced hull design, HUDSON have also worked with composite material suppliers, adapting aerospace technology to create the new proprietary SHARK carbon.

HUDSON use entirely ‘pre-preg’ carbon in every hull and carbon rigger they produce. The same material found in F1 racing cars, it’s by far the most laborious and time consuming way of building boats but ensures the highest integrity and quality is achieved in the finished product. It is also safer for their workers’ health, avoiding wet resin exposure and sensitivity. “It adds much more work for us in the finishing stages, not to mention cost, but if there is a choice between traditional and advanced, there is only one way HUDSON will ever go.”

HUDSON were the first boat builder in the world to convert it's fleet entirely to composite construction and aluminium wing rigger technology. Today, it’s the industry standard.

Following a lengthy development process, the strength and resilience of the carbon wings HUDSON brought to market defies belief. They have developed a carbon rigger which, they tell me, can withstand most catastrophic impacts. Eager to prove it, in what I imagine is a favourite party trick, I am handed a lump hammer and encouraged to hit one of the carbon riggers, “as hard as you can!” From what we have seen so far it’s hardly a surprise the rigger prevails. I barely crack the clear coat.

There are three key parts to manufacturing world class rowing shells, according to Craig. “Performance is key of course - it’s a performance sport and that ultimately will determine which boat is considered the best. The second critical factor is the function, the ergonomics, and the fit to the athlete; how the athlete feels in the boat is absolutely critical. It’s about how we can collaborate better with the athlete or coach to improve that.” HUDSON has built a network of coaching ‘allies’ around the world. From ex US Olympic and current University of California Berkeley Head Coach Mike Teti, to legendary bio-mechanist, rowing author and Western University head coach Volker Nolte - a select group of some of the sport’s most knowledgeable coaches provide HUDSON real world testing and expert feedback before anything is released onto market. The third part according to Craig, is the aesthetics or the cosmetics of the boat. “Anything that has a luxury price tag - people want it to look the part. So we’re pushing the innovation, working with coaches and athletes at a level that we believe nobody else is, and we’re also ensuring it looks fast too.”

The HUDSON ‘USP’ (Ultimate SHARK Predator) looks fast. The pinnacle of boat design and manufacturing, it sits at the top of their product line. True to their mission of focusing only on producing the best, HUDSON doesn’t make a budget option. The ‘SP’ (SHARK Predator) line was built to win Olympic finals, but the ‘USP’ is another level up. A ‘concept’ boat if you will. Conceived during a conversation on the banks of Dorney Lake at the Olympics in London, the principal was simple - Jack, Glen and Craig, simply asked themselves “What could we build if money and imagination were no object?” The ideas they came up with that day, still saved on Glen’s phone, became the blueprint for what would ultimately be the ‘USP’ boats. “Ruling out the completely non-viable, we boiled the list down to some of the things you see in those boats today. A lot of it is not a leap in anything other than people’s preconceptions.” The jewel in HUDSON’s crown, it defines what is possible from a racing shell. “It came at a point in our history where we were able to move incredibly fast”, reflects Glen. “That boat would normally be a five-year development project and we killed it in 18 months. It took everything we had in terms of human and monetary capital, but the end product is amazing.”

As the tour concludes, I can’t help but think, with their ethos of relentless improvement, impeccable customer service and a staff made up of competitive rowers, master engineers and skilled craftsmen, does it get better than this? “We don’t want to be the biggest, we don’t want to build the most boats (they currently produce around 600 per year), we just want to do what we do, better than anyone one in the world.” And having seen it for myself, I would say they do. With a purpose-built workshop about to open in the UK, a new website about to launch with its ‘Shark Tank’’ feature, which will allow customers to chart their boat through every step of the build process and another busy Olympics for HUDSON around the corner, where do they go from here? “We can’t reveal too much, but I can say that in five years’ time, where we are going will make what we do now appear standard. We are already working on the boats for the Tokyo 2020 cycle and there are some exciting things in the pipeline”. With our tour through the factory over and time to reflect, it occurs to me - if anyone can eclipse the HUDSON operation I’d seen that day, it will be the HUDSON of tomorrow.